Ngwongwo ụlọ ọrụ 0.35mm- 50.8mm HRC50-55 ọkụ AISI304 316 430 440 igwe anaghị agba nchara eji eme ihe

Nkọwa ngwaahịa

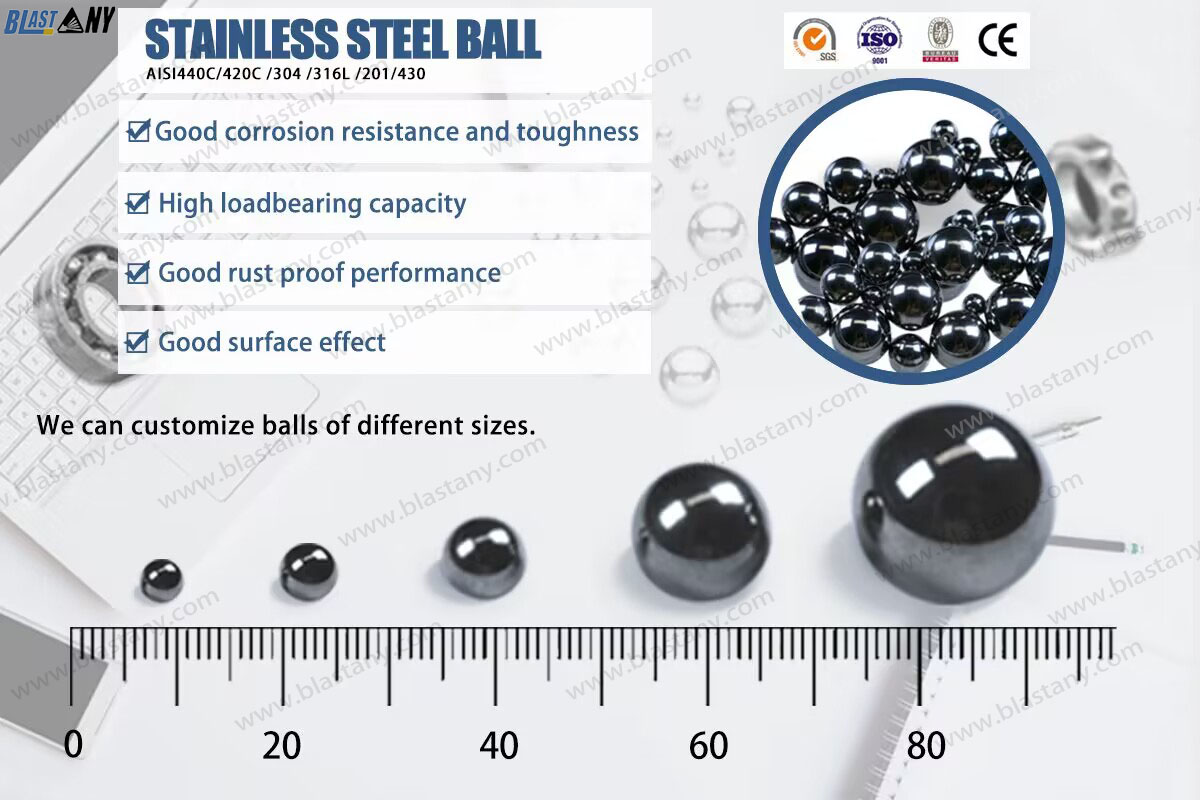

Bọọlụ igwe anaghị agba nchara nwere ike iguzogide corrosion site n'aka ndị ọrụ dị ka ihe ngwọta oxidizing, ọtụtụ kemịkalụ organic, nri nri na ngwọta sterilizing. Ha na-eguzogide obere sulfuric acid. Ngwongwo na-abụghị magnetik dị mgbe a rịọrọ ya. Ngwa gụnyere aerosol, sprayers, usoro mgbapụta mkpịsị aka, igwe igwe mmiri ara ehi, ngwa nhazi nri na ngwa ahụike.

AISI 440C igwe anaghị agba nchara

Akụkụ: 0.35mm-50.8mm

Ọkwa: G10, G16, G40, G60, G100, G200.

Isi ike: HRC56-58,Hartford 440C igwe anaghị agba nchara bọọlụ na-agafe agafe iji wepụ ihe mmetọ ígwè n'efu ma mee ka e guzobe ihe nkiri na-enweghị isi na-akpaghị aka.

Magnetik: magnetik ígwè, magnetik

Atụmatụ: elu nkenke, ezigbo nguzogide corrosion, nchara siri ike na iyi nguzogide.

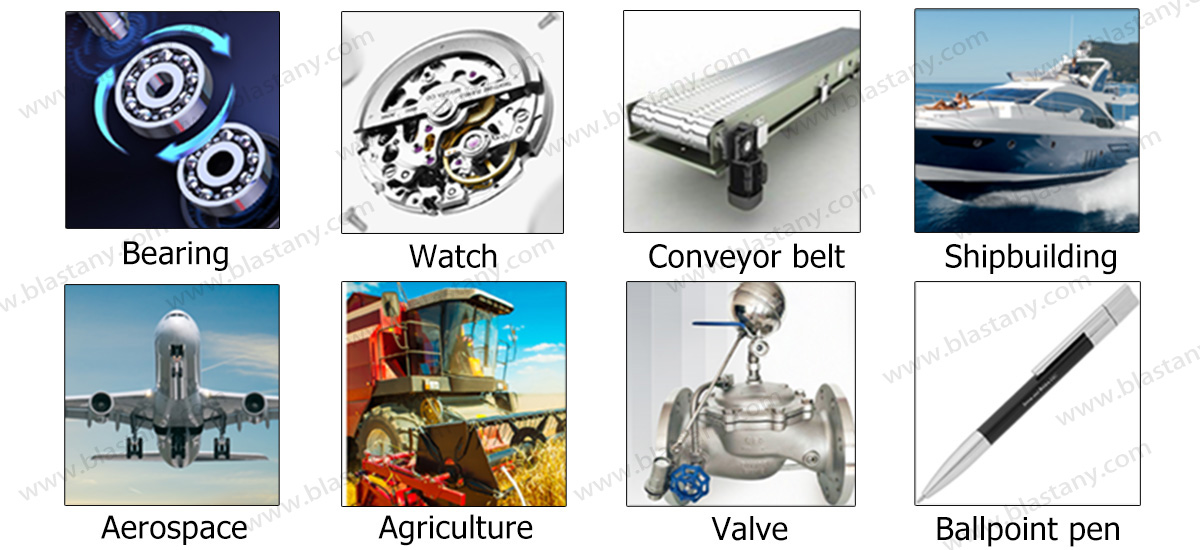

Ngwa: Bearings, stamping, hydraulic akụkụ, valves, aerospace, akàrà, refrigeration akụrụngwa, elu-nkenke ngwá, wdg.

| Ngwakọta kemịkalụ | ||||||||

| AISI 440C | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.95-1.10 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.60 | 16.0-18.0 | 0.75 | |

AISI 420C igwe anaghị agba nchara

Akụkụ: 0.35mm-50.8mm

Ọkwa: G10-G1000

Isi ike: HRC50-55

Magnetik: Martensitic ígwè, magnetik, Ezi mgbochi nchara, ike siri ike, AISI 420 igwe anaghị agba nchara bọọlụ na-egosipụta àgwà dị mma na ịdị ike. Isi ike dị ntakịrị na nguzogide corrosion dị ukwuu, ma e jiri ya tụnyere 440C.

Atụmatụ: A maara nke ọma dị ka igwe anaghị agba nchara, ezigbo nguzogide corrosion na ike siri ike.

Ngwa: ụdị nile nke nkenke igwe, bearings, eletriki akụrụngwa, ezinụlọ ngwa, auto akụkụ, wdg

| AISI 420C (4Cr13) | C | Si | Mn | P | S | Ni | Cr | Mo |

| 0.36-0.43 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.60 | 12.0-14.0 | ≤0.60 |

430 igwe anaghị agba nchara

Dayameta: 1MM-50.80MM

Isi ike: HRC26

Ọkwa: G10-G1000

Atụmatụ: ọnụ ala dị ala, nchara na-adịghị mma.

Ngwa: ngwaike, ihe ịchọ mma, ngwa, ihe ịchọ mma, ụlọ ọrụ, ụlọ ọrụ ndị nwere obere ihe achọrọ maka ịrụ ọrụ mgbochi. Ihe ịchọ mma agitators, ntu ntu na eyeliners, ndị na-ekpo ọkụ ọkụ, ngwa nha. na bọọlụ valvụ.

| AISI 430 | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.12 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | - | 16.0-18.0 | - |

AISI 304 igwe anaghị agba nchara

Ogo: 0.5mm-63.5mm

Ọkwa: G80-G500

Isi ike: ≤HRC21

Igwe Igwe Ọdụdọ: Austenitic ígwè, na-abụghị magnetik

Atụmatụ: ike nchara na-eguzogide, ezi corrosion resistance.widely eji, ezi nchara proof arụmọrụ, ezi elu mmetụta, gburugburu ebe obibi asambodo.

Ngwa: Ngwa ụlọ dị ka valvụ, karama na-esi ísì ụtọ, ntu ntu, karama ụmụaka, akụkụ akpaaka, ikuku ikuku, ngwa eletriki, ihe ịchọ mma, slide bear, akụrụngwa ahụike, ọla na ọtụtụ ụlọ ọrụ ndị ọzọ.

| Ngwakọta kemịkalụ | |||||||

| AISI 304 | C | Si | Mn | P | S | Ni | Cr |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.5 | 18.0-22.0 | |

AISI 316L igwe anaghị agba nchara

Ogo: 1.0mm-63.5mm

Ọkwa: G80-G500

Isi ike: ≤HRC26

Igwe Igwe Ọdụdọ: Austenitic ígwè, na-abụghị magnetik

Atụmatụ: nke kacha adabara maka ụlọ ọrụ nwere nnukwu ihe mgbochi corrosion chọrọ, yana ikike mgbochi nchara siri ike, ezigbo nguzogide corrosion (ewezuga acid chloridric), Ọ bụghị austenitic inox siri ike.

Ngwa: AISI 316L igwe anaghị agba nchara bọl nwere ike ji mee ihe maka ahụike akụrụngwa, chemical ụlọ ọrụ, ụgbọ elu, aerospace, plastic ngwaike, senti karama, sprayer, valves, ntu Polish, moto, mgba ọkụ, ígwè, ịsa igwe, friji, ikuku conditioners, ọgwụ ihe, akpaaka akụkụ, bearings, ngwá, karama.

AISI 316L igwe anaghị agba nchara

| Ngwakọta kemịkalụ | ||||||||

| AISI 316L | C | Si | Mn | P | S | Ni | Cr | Mo |

| ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | |

Nkwakọ ngwaahịa ngwaahịa

A) Nkwakọ ngwaahịa dị n'ime: A na-enye nkwakọ ngwaahịa mmanụ akọrọ dị ka mkpa gị si dị.

B) Nkwakọ ngwaahịa elu:

1) drum ígwè + osisi / ígwè pallet.

2) 25kg poly bag + katọn + osisi pallet ma ọ bụ igbe osisi.

ahaziri mbukota.

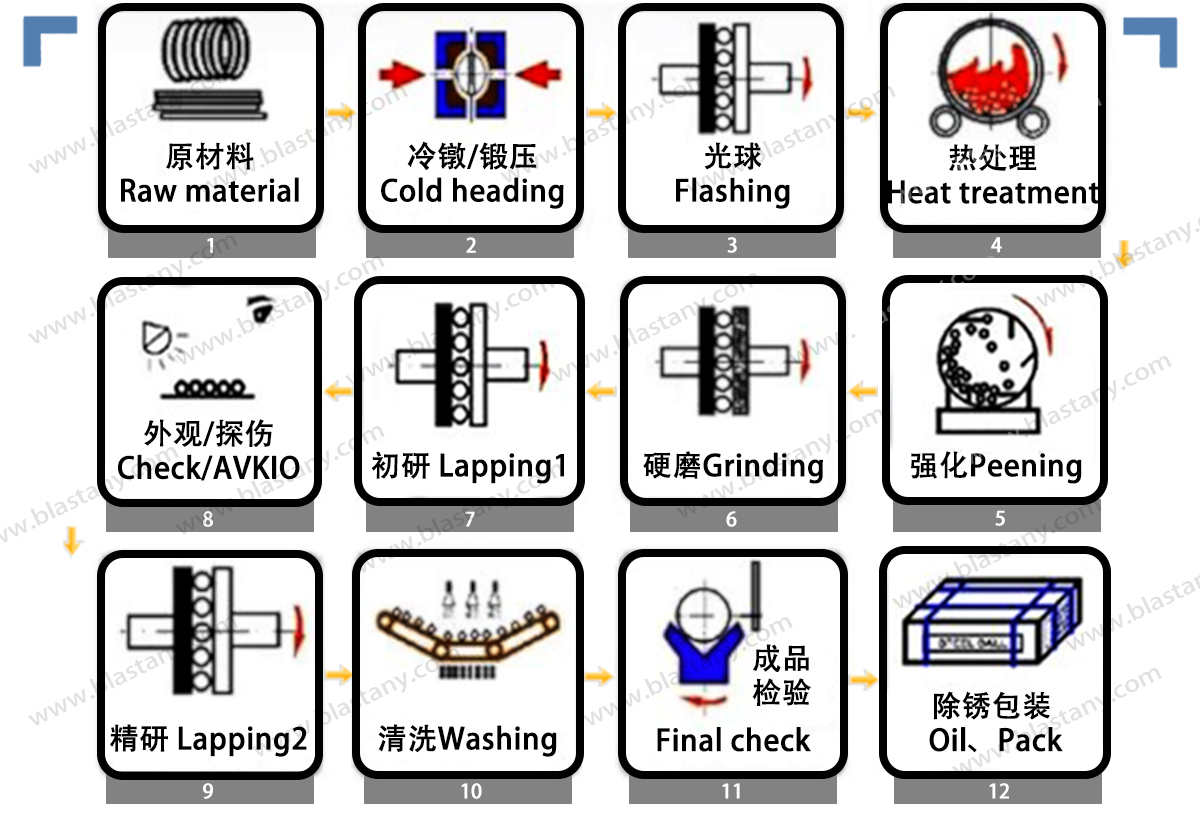

Usoro ngwaahịa

| Igwe anaghị agba nchara anyị gụnyere 440C 420C 304 316 201, ihe mejupụtara kemịkalụ dị ka ndị a | |||||||||

| Ngwakọta kemịkalụ (%) | C | Cr | Si | Mn | P | S | Mo | Ni | Cu |

| AISI440C SS bọọlụ | 0.95-1.2 | 16-18 | ≤0.80 | ≤0.80 | ≤0.04 | ≤0.03 | ≤0.75 | ≤0.6 | ---- |

| AISI420C SS bọọlụ | 0.26-0.43 | 12-14 | ≤0.80 | ≤1.25 | ≤0.035 | ≤0.03 | ≤0.6 | ≤0.6 | ---- |

| AISI304 SS bọọlụ | ≤0.08 | 18-22 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | ---- | 8-10 | ---- |

| AISI316L SS bọọlụ | ≤0.08 | 16-18 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 2.0-3.0 | 12-15 | ---- |

| AISI201 SS bọọlụ | ≤0.15 | 16-18 | ≤1.0 | 5.5-7.5 | ≤0.045 | ≤0.03 | ---- | 0.35-0.55 | 1.82 |

| AISI430 SS bọọlụ | ≤0.12 | 16-18 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | ---- | ---- | ---- |

Usoro mmepụta

Nyocha ihe akụrụngwa

Akụrụngwa na-abịa n'ụdị waya. Nke mbụ, ndị na-enyocha mma na-enyocha ngwa ahụ n'anya iji chọpụta ma ọ dị mma ruo akara ma ọ bụrụ na ọ nwere ihe ndị nwere nkwarụ. Nke abuo, nyochaa dayameta ma nyochaa asambodo akụrụngwa.

Isi oyi

Igwe isi oyi na-egbutu ogologo waya a kapịrị ọnụ ka ọ bụrụ slugs cylindrical. Mgbe nke ahụ gasịrị, akụkụ abụọ nke akụkụ akụkụ nke isi ya na-anwụ na-eme ka slug ahụ bụrụ ọdịdị okirikiri. A na-eme usoro ịhịa aka n'ahụ n'ime ụlọ ma na-eji ntakịrị ihe mgbakwunye na-eme ka oghere ndị nwụrụ anwụ jupụta kpamkpam. A na-eme isi okwu oyi n'ọsọ dị oke elu, yana nkezi ọsọ nke otu nnukwu bọọlụ kwa nkeji. A na-ebute bọọlụ ndị nta ahụ na ọsọ nke bọọlụ abụọ ruo anọ kwa nkeji.

Na-egbuke egbuke

N'oge usoro a, a ga-ewepụ ihe karịrị ihe a na-eme gburugburu bọọlụ. A na-agafe bọọlụ ndị ahụ ugboro ole na ole n'etiti efere igwe nkedo abụọ gbawara agbawa na-ewepụ obere ihe ngafe ka ha na-atụgharị.

Ọgwụgwọ okpomọkụ

Mgbe ahụ, a ga-edozi akụkụ ahụ okpomọkụ site na iji usoro nkwụsị na okpomọkụ. A na-eji ọkụ rotary eme ihe iji jide n'aka na akụkụ niile nwere otu ọnọdụ. Mgbe ọgwụgwọ okpomọkụ nke mbụ gasịrị, a na-agbanye akụkụ ndị ahụ n'ime mmiri mmanụ. Nke a ngwa ngwa jụrụ oyi (mmanụ quenching) na-arụpụta martensite, a nchara na-adọ nke e ji elu ike ike na elu iyi Njirimara. Ọrụ iwe ọkụ na-esote na-ebelata nrụgide dị n'ime ruo mgbe njedebe ikpeazụ akọwapụtara nke bearings ruru.

Na-egweri

A na-egweri ma tupu na mgbe ọgwụgwọ okpomọkụ gasịrị. Mechaa egweri (nke a makwaara dị ka Grinding Hard) na-ebute bọọlụ nso na ihe ikpeazụ ọ chọrọ.Ọkwa nke bọọlụ ọla nke ọmabụ ihe atụ nke n'ozuzu ya nkenke; ọnụ ọgụgụ dị ala, otú ahụ ka ọ bụ bọlbụ. Ọkwa bọọlụ na-agụnye nnabata dayameta, okirikiri (sphericity) na ịdị njọ nke elu nke a na-akpọkwa imecha elu. Imepụta bọọlụ ziri ezi bụ ọrụ ogbe. A na-ekpebi nha nza site na nha igwe eji arụ ọrụ egweri na ịsa nri.

Ịkụ ụra

Lapping dị ka egweri mana ọ nwere obere mwepụ ihe onwunwe dị ala. A na-eji efere phenolic abụọ na ezigbo abrasive slurry dị ka uzuzu diamond. Usoro n'ichepụta ikpeazụ a na-eme ka ọ dịkwuo elu. A na-eme ịra ụra n'ihi akara akara bọọlụ dị elu ma ọ bụ nke zuru oke.

Nhicha

Ọrụ ihicha wee wepụ ihe ọ bụla na-edozi mmiri na ihe abrasive na usoro mmepụta. Ndị ahịa na-arịọ maka ihicha ihe ndị ọzọ siri ike, dị ka ndị nọ na ngalaba microelectronics, ụlọ ọrụ ahụike ma ọ bụ nri, nwere ike were ohere nke Hartford Teknụzụ nhọrọ ihicha ọkaibe.

Nyocha anya

Mgbe usoro nrụpụta nke mbụ gasịrị, bọọlụ nchara nchara nke ọma na-enweta ọtụtụ nlele njikwa njikwa n'ime usoro. A na-eme nlele anya iji lelee ntụpọ dị ka nchara ma ọ bụ unyi.

Roller Gauging

Roller gauging bụ usoro nhazi 100% nke na-ekewa ma bọọlụ nchara dị n'okpuru na nke karịrị nkenke. Biko lelee anyị ichevidiyo na usoro ihe nleba anya.

Njikwa ogo

A na-enyocha ọtụtụ bọọlụ ziri ezi iji hụ na ọkwa ọkwa chọrọ maka ndidi dayameta, okirikiri na ịdị nhịahụ elu. N'oge usoro a, a na-enyochakwa njirimara ndị ọzọ dị mkpa dị ka ike siri ike, na ihe ọ bụla a na-ahụ anya.

Ụdị ngwaahịa