Ike ike dị elu na-eguzogide Cut Waya Shot

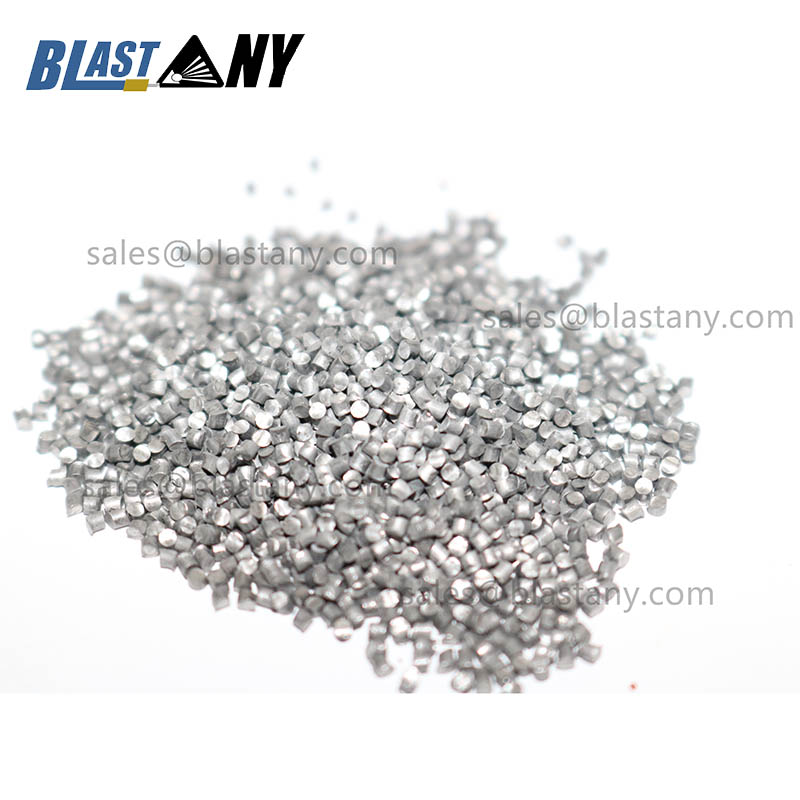

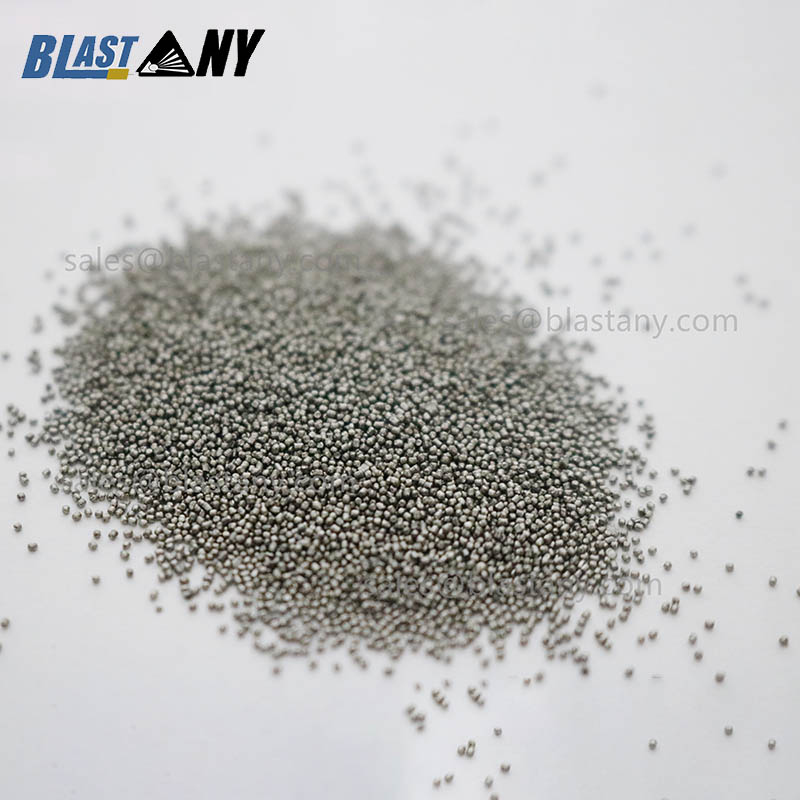

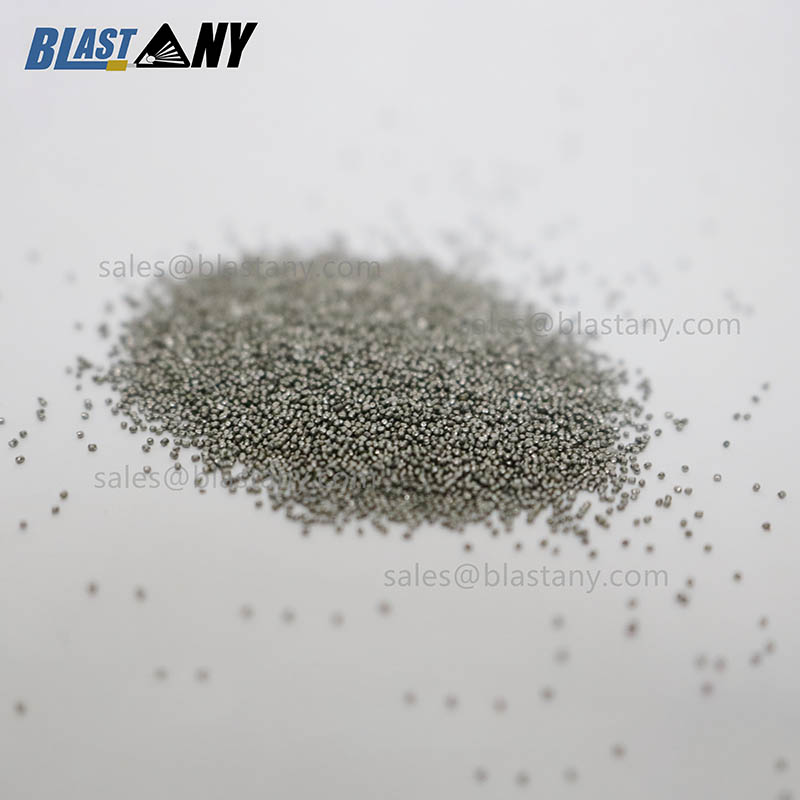

Ụdị ogbugbu ịcha waya ígwè

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Oke ngwa nke ọgwụ ịcha waya

1. Steel waya ogbugba ọnwụ ọnwụ ike: gbara agbawa ume ike, gbaa gbawara agbawa ike nke okpomọkụ mesoo akụkụ, gbawara agbawa ike nke gia.

2. Steel waya gbara peening: ígwè ogbugba peening, ígwè ájá gbawara, ụgbọ mmiri gbawara agbawa, ígwè ogbugba peening, ígwè ogbugba peening.

3. Steel waya gbara igbubi ihicha: ogbugba ogbunigwe ihicha, ogbugba ogbunigwe ihicha, ịnwụ nkedo ihicha, nkedo ogbugba nhicha nhicha, forging ogbunigwe ihicha, forging ogbugba ogbugba nkedo nkedo nkedo ájá ihicha efere ígwè ihicha, ígwè nhicha, ígwè nhicha, H-beam ígwè. ihicha, nchara Ọdịdị ihicha.

4. Steel waya ọnwụ ogbugba ogbugba derusting: gbara agbawa derusting, shot peening derusting, nkedo derusting, forgings derusting ígwè efere derusting, forgings derusting, ígwè derusting, H-beam derusting ígwè Ọdịdị derusting.

5. Steel waya ọnwụ ogbugba ájá: aja ọgwụgwọ.

6. Steel waya gbara igbubi pretreatment: mkpuchi pretreatment, mkpuchi pretreatment, elu pretreatment, ụgbọ mmiri pretreatment, ngalaba ígwè pretreatment, ígwè pretreatment, ígwè pretreatment, ígwè Ọdịdị pretreatment.

7. Steel waya gbawara agbawa: ígwè efere ogbugba ogbunigwe, ígwè ogbugba ogbunigwe, ígwè ogbugba ogbunigwe.

Ọdabara akụrụngwa maka ígwè waya ogbugbu ọnwụ

A na-eji waya ịgba ụta ígwè eme ihe maka ahịrị mmepụta ígwè pretreatment, ahịrị mmepụta ihe nchara, ahịrị nchara pretreatment mmepụta, igwe agba agba agba, ngwa ịgba agba agba, ngwa ịgba agba agba, igwe agba aja aja, akụrụngwa na-agba agba aja abrasive.

Nka nka

| Ngwaahịa | Bee ọkụ waya | |

| C | 0.45 ~ 0.75% | |

| Mn | 0.40 ~ 1.20% | |

| Ngwakọta kemịkalụ | Si | 0.10 ~ 0.30% |

| S | 0.04% | |

| P | 0.04% | |

| Microhardness | 1.0mm 51 ~ 53 HRC (525 ~ 561HV) | |

| Ike ntachi obi | 1.0mm 1750 ~ 2150 Mpa | |

| Njupụta | 7.8g / cm3 | |

Ụdị ngwaahịa