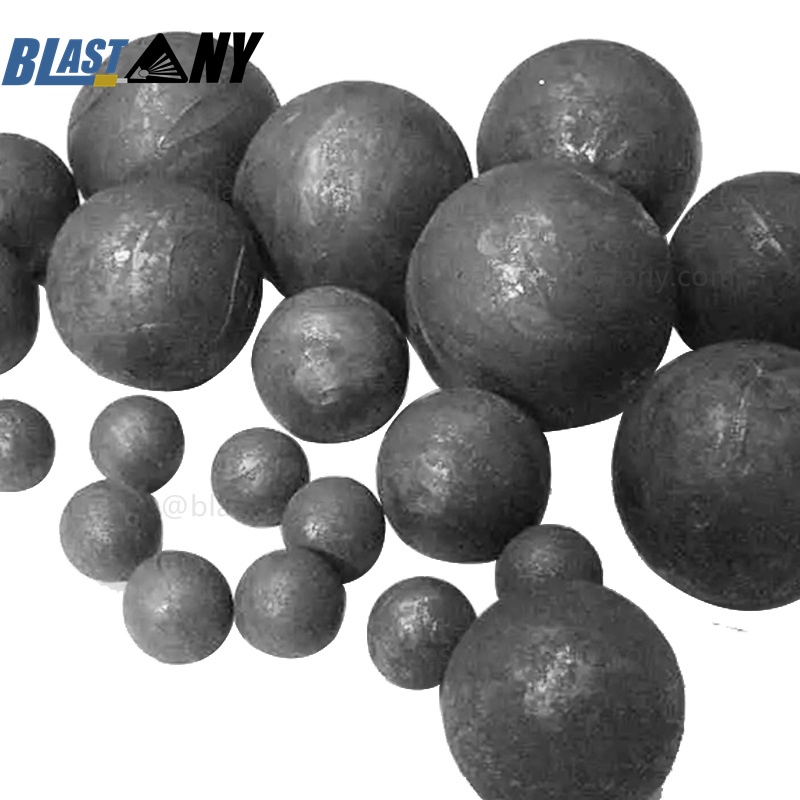

Na-egweri bọọlụ

Usoro mmepụta

Mgbe ịlele na ule gburugburu alloy ígwè mmanya ihe onwunwe, na mmepụta nwere ike malite dị ka size nke ígwè bọl.The ígwè forging na-ekpo ọkụ na a ụfọdụ okpomọkụ site intermediating na ugboro ọkụ ọkụ iji hụ na irè ọgbọ nke variables na forging;A na-eziga nchara nchara na-acha uhie uhie na hama ikuku ma na-ahazi ya site n'aka ndị ọrụ nwere nkà.Mgbe forging na-acha uhie uhie na-ekpo ọkụ ígwè bọl ozugbo n'ime JUNDA pụrụ iche e mere okpomọkụ ọgwụgwọ ngwá maka quenching na tempering okpomọkụ ọgwụgwọ, elu na edo hardness uru nke ígwè bọl nwere ike hụ.

Njirimara

1.High mmetụta siri ike

2.Compact nzukọ

3.High iyi mgbochi

4.Obere nkwụsịtụ

5.Uniform hardness

6.Ọ dịghị deformation

Mbukota na Ụgbọ njem

| Akpa akpa | Ịgba ígwè | |

| Net arọ 1000kgs maka bọọlụ nha niile | Nha bọọlụ | Nha ịbụ |

| 20-30mm | 930-1000KGS | |

| 40-60mm | 900-930KGS | |

| 70-90mm | 830-880KGS | |

| 100mm na n'elu | 830-850KGS | |

| Akpa:73×60cm, 1.5KG, 0.252CBMỊgba:60×90cm, 15-20KG, 0.25CBM Pallet Single: 60×60×9cm, 4-6KG:Ugboro abụọ:120×60×10cm, 12-14KG | ||

Usoro nka

| Nka na ụzụ parameters nke forging ígwè bọọlụ | ||||||||||||

| Inch | Nha | T ibu | Ndigide (mm) | Ihe onwunwe | Isi ike elu (HRC) | Isi ike olu (HRC) | ||||||

| 3/4" | D20mm | 0.037+/-0.005 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 1" | D25mm | 0.072+/-0.01 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/4" | D30mm | 0.13+/-0.02 | 2+/-1 | B2 | 63-66 | 63-66 | ||||||

| 11/2" | D40mm | 0.30+/-0.04 | 2+/-1 | B2 | 62-66 | 62-66 | ||||||

| 2" | D50mm | 0.6+/-0.05 | 2+/-1 | B2 | 62-65 | 61-64 | ||||||

| 21/2" | D60mm | 1.0+/-0.05 | 2+/-1.5 | B2 | 62-65 | 60-62 | ||||||

| 3" (ọkụ na-ekpo ọkụ) | D80mm | 2.0+/-0.06 | 3+/-2 | B3 | 60-63 | 60-62 | ||||||

| 3" (Egburugburu) | D80mm | 2.1+/-0.06 | 3+/-2 | B3 | 60-62 | 53-57 | ||||||

| 31/2" | D90mm | 3.0+/-0.07 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 4" | D100mm | 4.1+/-0.15 | 3+/-2 | B3 | 60-63 | 59-62 | ||||||

| 5" | D125mm | 8.1+/-0.3 | 3+/-2 | B3 | 59-62 | 55-60 | ||||||

| Ngwakọta kemịkalụ | C% | Si% | Mn% | kr% | P% | S% | Ni% | |||||

| B2 | 0.72-1.03 | 0.15-0.35 | 0.3-1.2 | 0.2-0.6 | ≤0.035 | ≤0.035 | i≤0.25 | |||||

| B3 | 0.53-0.88 | 1.2-2.00 | 0.50-1.20 | 0.7-1.20 | ≤0.035 | ≤0.035 | i≤0.25 | |||||

Ụdị ngwaahịa